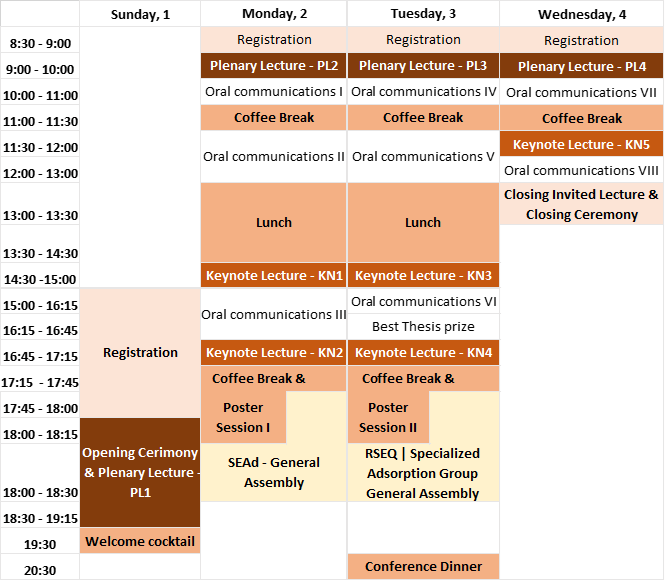

Program

Scientific Program

Opening Lecture

Alírio Rodrigues - Faculty of Engineering, University of Porto (FEUP), Porto

25 Abril 1974 - 50 years

The democratization of higher education and scientific research in Portugal

My adsorption journey

Plenary Lectures

Susana Valencia – ITQ / CSIC, Valencia

Revealing the Potential of Zeolites: Enhancing Solutions for Separation Processes

Gas and vapour separations can be complex and energy-intensive, driving the search for more sustainable options. The use of porous materials as selective adsorbents has been proposed as a very efficient solution. Zeolites, in particular, can be tailored to meet the specific needs of these separations, maximizing unit production and diminishing energy demand.

This presentation aims to show how zeolites can be applied in different separations, such as those involving CO2 adsorption and other processes where all silica zeolites can perform successfully. Examples include separations of olefins from paraffins, separations of linear and monobranched from multibranched alkanes, and the recovery of bioalcohols from fermentation media by vapour phase adsorption processes.

These examples illustrate how the properties of zeolites influence adsorption processes and how these properties can be modified to be adapted to the required separation with the objective of enhancing productivity and selectivity using these materials as selective adsorbents.

José Paulo Mota – FCT/UNL, Lisboa

Continuous Chromatographic Downstream Processing of Biopharmaceuticals

Continuous manufacturing has seen widespread adoption across various industries, yet its integration into biotechnology has been met with hesitation, as traditional batchwise processing remains the norm. However, transitioning to continuous operations holds immense potential to enhance productivity and significantly reduce the operational footprint. Furthermore, continuous processes enable robust purification of delicate biomolecules, facilitated by a comprehensive suite of unit operations tailored for continuous downstream processing in biopharmaceuticals.

Of these operations, chromatography stands out as particularly advanced in continuous mode, having resolved the inherent challenges associated with batch definitions. This advancement not only streamlines regulatory compliance but also paves the way for broader implementation of continuous downstream processing. The impetus for embracing continuous manufacturing strategies in the future will be driven by economic pressures, operational flexibility, and considerations for parametric release.

A straightforward approach to continuous chromatography involves running multiple columns in parallel, allowing for seamless cycling of loading, washing, elution, regeneration, and re-equilibration processes. While each step may have differing durations, optimizations can be made to consolidate steps within a single cycle, thereby enhancing efficiency. Nonetheless, loading often emerges as the most time-intensive step, potentially leading to idle columns and reduced productivity. Strategies such as distributing loading across multiple columns can mitigate this issue, albeit at the expense of increased equipment costs.

Remarkable progress has been made in industrial-scale continuous purification processes, notably through rapid cycling of membrane chromatography units, enabling the processing of significant volumes of cell culture supernatant. Moreover, advancements in high-throughput development and modeling have facilitated the rapid optimization of adsorption and elution conditions, seamlessly translatable from batchwise to continuous operations.

In the realm of chromatography applied to biomolecules, scalability poses no inherent challenge, with various operation principles extensively explored. Notable among these are rotating chromatography devices and periodic countercurrent chromatography techniques, which operate in a pseudocontinuous manner, achieving cyclic steady state operation.

This review aims to elucidate the downstream processing of biopharmaceuticals, with a focus on the impementation of continuous chromatography. The pivotal drivers for transitioning from batchwise to continuous operation encompass gains in productivity, operational flexibility, and the potential for implementing process-control strategies essential for parametric or real-time release. While continuous chromatography introduces complexity, its benefits in productivity and flexibility far outweigh the challenges, making it an increasingly attractive prospect for biotechnological applications.

Mercedes Maroto - Heriot-Watt University, Edinburgh

Keynote Lectures

José Antonio Delgado Dobladez - Universidad Complutense de Madrid, Madrid

Hybrid Membrane-PSA Systems for Hydrogen Recovery from Ammonia Cracking and CO2 Capture from Flue Gas

Hybrid membrane-PSA systems can be advantageous over systems based on only one of these technologies for performing bulk gas separations. In this work the performances of hybrid membrane-PSA systems for hydrogen recovery from ammonia cracking and CO2 capture from flue gas are evaluated and compared with the one of single PSA processes, by simulation with PSASIM® software.

Mirjana Minceva - Technical University of Munich, Munich

New possibilities with liquid stationary phases

In liquid-liquid chromatography, centrifugal partition chromatography (CPC), and countercurrent chromatography (CCC), the mobile phase and the stationary phase are the two phases of a liquid biphasic system composed of two or more solvents. The stationary phase is held in place during operation by the application of centrifugal force in a specially designed column. Separation of a sample mixture is achieved due to the different distribution of the solutes between the two liquid phases. Either phase of the biphasic solvent system, the upper or the lower phase, may be used as the stationary phase. The roles of the phases and flow direction may be switched during a separation run, giving rise to various operating modes not otherwise realizable with solid stationary phases (adsorbents). These features, combined with the nearly limitless choice of solvents, make the technology extremely versatile and allow for the creation of tailor-made biphasic liquid systems, i.e., tailor-made mobile and stationary phases. This high operational flexibility renders centrifugal partition chromatography highly adaptable to different separation tasks. This talk will cover recent developments in liquid-liquid chromatography, focusing on process design and optimization using a model-based approach with the perspective “from molecule to process”.

Youssef Belmabkout - ACER CoE, Morocco

Quest of porous materials via the valorization of organic and inorganic Wastes

The large-scale production of various end products has increased industrial activities, leading to hazardous pollutants in the environment. Research is focused on capturing these pollutants and valorizing industrial waste into valuable commodities, such as porous physical adsorbents like MOFs, mesoporous silicas, and zeolites. Producing these materials on a large scale is challenging due to the high cost of precursors. Using waste sources for their preparation could address sustainability and environmental concerns. This study transforms phosphogypsum, a phosphate industry waste product, into advanced Ca-MOFs and zeolites. Additionally, tannery effluents and waste plastic bottles were converted into water-adsorbing Cr-terephthalate MOFs, showing potential for water-related applications. Various techniques confirmed the structural attributes and performance of these porous sorbents. The study represents significant progress in sustainability, circular economy goals, and scaling up the production of adsorbents from solid-state materials.

Azahara Luna Triguero - TU/e, The Netherland

Thermochemical Energy Storage of Traditional and Blended Refrigerants in Porous Materials

Traditional refrigerants, known for their high Global Warming Potential (GWP), are being phased out from most applications. This research explores their potential use in adsorption-based energy storage systems. By combining micro- and mesoporous materials with refrigerants and evaluating their performance in energy storage, we aim to gain a better understanding of the underlying mechanisms and identify more sustainable alternatives. One of the alternatives being considered is the use of blended refrigerants. This work focuses on the challenges of assessing and predicting the behavior of classical refrigerants, such as the crucial role of defined interactions and molecular models in the simulation. Additionally, it assesses the impact of postprocessing models and data analysis on performance indicators, providing insights into the efficiency and behavior of refrigerants-materials pairs. This research aims to evaluate the energy storage potential of blended refrigerants in porous materials with the ultimate goal of minimizing the environmental impact of refrigeration systems and establishing key performance indicators that contribute to the development of more sustainable solutions.

Carlos Grande , KAUST, Saudi Arabia

The role of adsorption in the production of bio-methane

Biogas is a sustainable source of energy that can be used to produce electricity but that can also be used for decarbonizing transportation. The emissions related to the transportation sector is 24% of total CO2 emissions and is a difficult sector to decarbonize as there are multiple source points. Bio-methane has the potential to have a significant share of this market.

Adsorption in general is a very suitable technique to assist in the production of bio-methane. Adsorption processes are available to remove contaminants from biogas like siloxanes, H2S and other minor molecules (biogas conditioning). Moreover, pressure swing adsorption (PSA) is a state-of-the-art technology for biogas upgrading (bulk removal of CO2). In recent years, adsorbent materials have also been used for enhanced storage of bio-methane. Indeed, using a suitable material in a storage tank, the pressure of bio-methane can be significantly reduced with tremendous impact in weight reduction of the storage tank.

In this work, we present recent developments in PSA technology for biogas upgrading, specifically in the deployment of new PSA cycles for different users depending on production volumes. We also introduce a new approach to make carbon-based monoliths for storage of bio-methane with tailored porosity with minimal impact in gas diffusion. Our ultimate objective is to demonstrate that adsorption technologies can have a significant role in transitioning to sustainable mobility in different regions of the planet.

Closing Lecture

José Luís Figueiredo - Faculty of Engineering, University of Porto (FEUP), Porto

RIA@Porto: 20 years later